Static electricity discharge (ESD) is a very common phenomenon that occurs during contact or separation of two objects. Due to an imbalance in electric charge, static electricity accumulates on the surface of an object and is released at the appropriate time, causing damage or destruction to surrounding electronic devices. Therefore, measures must be taken in electronic device manufacturing and use to prevent ESD from causing damage to the equipment.

Principles of ESD

ESD originates from the human body, including clothing, ground, and other objects’ accumulated charges, especially in dry weather. When a person approaches charged objects, their body accumulates an opposite charge, creating an electrical potential difference. When the distance between a person and a charged object decreases to a certain range, the charge will form an arc discharge through the gas in the air. This discharge process is very brief, usually only taking a few nanoseconds. However, even such a short time is enough to transfer a lot of energy to the attacked equipment, causing many problems.

Protection against ESD

To protect electronic devices from ESD damage, a series of protection measures must be taken. Here are some common protective measures:

- Use anti-static eliminators

Anti-static eliminators can help achieve static electricity release and protect the surrounding equipment from damage. These eliminators typically direct charges to the earth, quickly releasing charges from the equipment and surrounding environment.

- Use ESD packaging materials

Using anti-static packaging materials can effectively protect electronic devices from ESD attacks. These materials can absorb and discharge static electricity, thereby reducing the risk of equipment being subjected to static electricity shock. Such packaging materials should be used to protect electronic devices during manufacturing, transportation, and storage processes.

- Grounding

Grounding can lead static electricity to the earth, protecting the equipment from damage. Ensuring good contact between the device and the earth is essential and can be achieved by using grounding ports or connectors.

- Use ESD suppression components

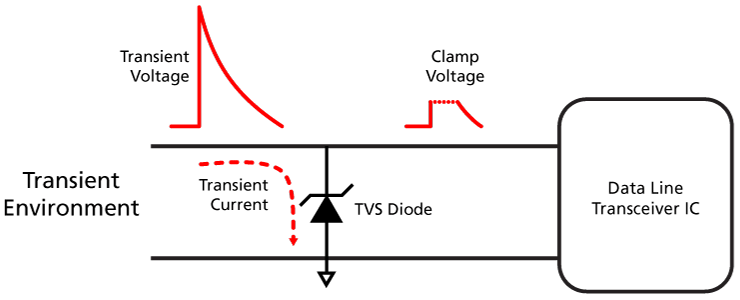

ESD suppressors are specifically designed to resist ESD attacks. They are commonly integrated into circuit boards to protect equipment from damage caused by ESD. These components can consume static electricity energy and release it into the earth.

Conclusion

ESD is a severe problem in electronic device manufacturing and use. A series of protection measures should be taken to effectively protect equipment from ESD attacks. Protective measures include the use of anti-static eliminators, anti-static packaging materials, grounding, and ESD suppression components. Only by taking this issue seriously can we ensure that our devices will not be harmed during operation.